Leak Detection

Leak Detection Using Tracer Gas

Using tracer gas is a proven method of locating and pinpointing hard to find leaks. Tracer gas can be used in gas and water services, distribution networks, pipelines in buildings, heating systems, pressurised communication cables, gas-filled high voltage power lines, and landfill sites sealed with double membrane layers.

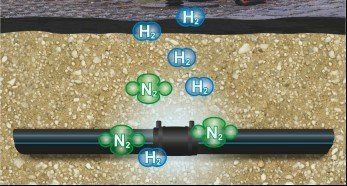

Detecting leaks by tracer gas involves feeding a mixture of 95% nitrogen (carrier gas) and 5% hydrogen into the pipelines or other equipment/ products being tested.

Hydrogen is one of the lightest gasses and due to this it escapes through the smallest of leaks and seeks the shortest route from the leak to the surface. Tracer gas permeates all cover layers such as asphalt, concrete and other seal coats. The gas is then detected by the highly sensitive, specialised sensor. Tracer gas is environmentally-neutral and once it has made its way up through the surface it quickly dissipates.

This diagram shows the Hydrogen in the tracer gas escaping through the leaking pipe before rising and permeating through the surface and being detected by the bell probe (above ground probe).

The low amount of hydrogen (just 5%) means that this method is safe. The gas is non-combustible and through the use of nitrogen as the carrier gas it can be safely used to locate leaks on gas mains and consumer piping.

Tracer gas is non-toxic and is permitted for use in drinking (potable) water networks. In addition to this it is non-corrosive and therefore has no effect on the pipework it is being run through.

Our tracer gas detection system has diagnostic probes for internal use. A bell type probe (pictured) is used for the detection of gas above ground and a bar hole probe for probing and confirming localisation of leaks in the ground.

We have a custom made trailer designed specifically to safely carry the tracer gas and equipment. This enables us to be mobile in our set up. As the feed hose and equipment can be set up quickly and efficiently, this reduces the set up time and enables us to be quick and efficient in locating hard to find leaks.

Leak Detection using Thermal Imaging

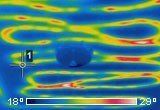

Using modern Thermal Imaging technology a leak can be located on a burst pipe behind obstacles with minimum disruption and no damage to your property.

Our Leak Detection engineers use more than one method of leak detection to confirm and accurately locate your leak. Thermal imaging cameras are used to find hidden leaks under floors, behind walls and are an essential part of our engineers’ tool kit.

Thermal imaging cameras record light as heat and can show this in a picture. The Infrared energy (thermal) is a light we can’t see but we can sense as heat. Thermal imaging cameras identify very small differences in temperature on the surface of different materials, highlighting the warmer and the colder surface areas providing evidence of where the leak is originating. Our engineers have many years of experience in detecting leaks and use their knowledge to analyse thermal imaging results against their other findings.

Thermal imaging cameras can look at large areas quickly compared to other types of leak detection methods and can see major losses of heat or potential damp problems on the exterior of your property.

Don’t waste any more time and money on trying to find that leak, call Leak Detection Specialists for a free non-obligation quote.

Benefits of Thermal Imaging

- Detects moisture in ceilings, flat roofs, behind walls and under floors.

- Records exterior property heat loss and damp detection

- Looks at large areas quickly

- Non destructive leak detection method

- Reduces your energy consumption and saves on your heating bills

Thermography is best suited to heating leaks and under floor heating matrix leaks.

Energy leakage our surveys will detail the areas of concern such as insulation problems or building fabric issues etc…

Flat roof surveys carried out with full colour photos attached to the report detailing the areas of concern and recommendations

Leak Detection using Acoustic Methods

Acoustic profiling uses ground and pipe sensitive microphones to enhance the sound of the leak. This method can help in pinpointing precise leak location

The principle behind electronic leak detection is that all leaks produce sounds. An electronic leak detection system operates on that principle known as acoustics or the principles of sounds. The electronic machine that is attached to a building's security system registers the sound made by leaks since it picks up sound waves and transmits their originating site using the safety system installed.

Leaks have different frequencies made by the type of leak whether coming from pipes that are under greater pressure or from pipes that are under lower pressure and from the contents of these pipes. These leaks transmit a frequency that is picked up by the electronic leak detector and is applied while being transmitted through the security system. The amplified sounds that the leak is making is picked up by a trained worker who is also given access to other information regarding the location of the leak found on the leak detection machine and on the type of leak based on the sounds it makes as well as the location.

An electronic leak detector is equipped with a transducer that is sensitive to sounds coming from a system of pipes. If a sound registers on the machine, it is transmitted to the security system at a higher frequency. The amplified leak is then detected and can be attended to immediately following detection. There are various sources that supply leak detectors or for electronic leak detectors. A plumber is an expert in installing and attending to leaks reported by an electronic machine designed especially to pick up on the acoustics made by sounds outside of pipes or leaks. An electronic leak detection machine finds leaks in water systems, toilets, drains, industrial pipes, steam pipes, oil pipes and other pipes transporting liquids. The principle of sound is what is used to detect leaks in pipes using an electronic leak detector.